> Home / Integrated Products / Adaptive Grinding

Adaptive tools for robotic grinding and polishing

Description

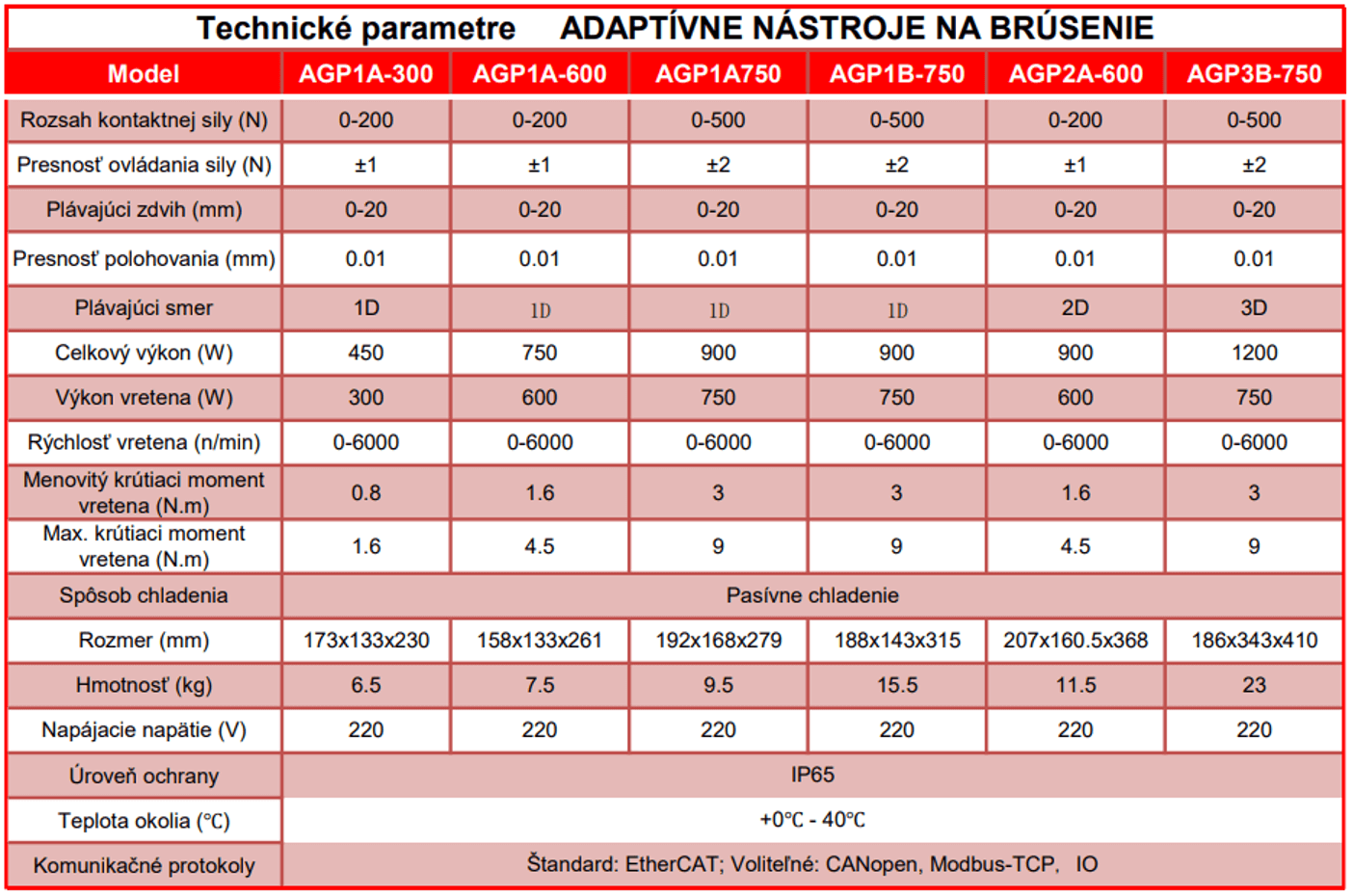

The top series of closed-loop adaptive force control grinding machines based on electro-hydraulic drive, optimized for grinding, polishing and deburring. The high-precision, flexible closed-loop force and position control and compact AGP structure make it an excellent choice for any grinding and polishing situation.

Power

✓ The tool incorporates an electro-hydraulic actuator for force control, which provides high-precision control, fast response, high rigidity, high power density and stable performance.

✓ The spindle uses a frameless torque motor, resulting in smaller size, higher torque and smoother operation. The system supports automatic tool exchange.

✓ Highly integrated system combined with instrumented sensors reduces size and weight and provides real-time feedback.

✓ Built-in interface designed for ease of use facilitates the adjustments available to the operator.

✓ S upport for different protocols, which simplifies communication with robots.

Benefits

✓ The tool incorporates an electro-hydraulic actuator for force control, allowing easy switching between force and position control modes.

✓ Higher power density, higher energy efficiency, higher torque, greater grinding force, lower dustiness.

✓ Comes with a highly integrated system with compact size and light weight, compatible with both collaborative and industrial robots.

✓ 2 20V power supply and work without outside air.

Application

AGP is compatible with collaborative and industrial robots, machine tools and is suitable for polishing, drawing, deburring and grinding for heavy-duty applications. Thanks to the unique force control technology, this grinding tool can achieve high-efficiency, high-precision adaptive grinding and polishing with low power consumption, low dust and low noise.

Suitable for a wide range of industries: automotive, consumer electronics, aerospace, shipbuilding, medical equipment, metallurgy, energy, petrochemical, etc.